Ballut Blocks has its origins in a small family business in the immediate postwar years. Joseph Vella started using his truck, usually used for agricultural purposes, to remove the rubble and debris from war damaged cities and towns to clear the way for reconstruction.

The First Truck

The first manual concrete block machine

Thereafter he secured from his father a piece of land in the family homestead of Ballut to operate a manual concrete block making machine.

Founders

Mr. Joseph Vella

Mr. Luigi Vella

Mr. John Vella

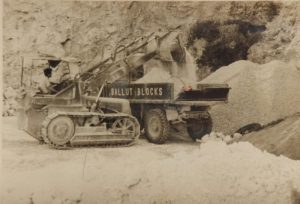

Soon he was joined by his brothers Louis and John and they put together a small construction business where they manufactured construction materials through rock excavation from a quarry in Ballut and produced concrete blocks from the same materials.

The three brothers slowly but surely grew this construction business adding mechanized machinery such as mechanical shovels and trucks for their own use and for contracting out, buying a new crusher for producing aggregates and also substituting the manual block machine with an automated one.

Aggregate and sand production the early days

Concrete blocks in the first years

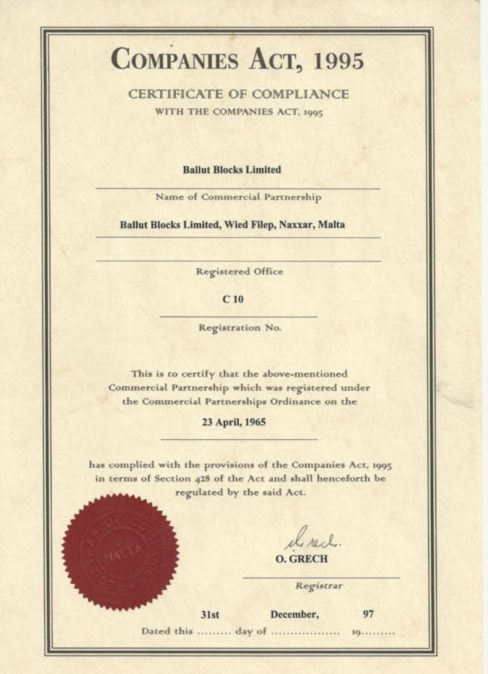

In 1950 the three brothers started calling their enterprise Ballut Blocks whilst in 1965 they incorporated one of the earliest and first construction limited liability companies in Malta with the registration number C10. The new company was situated at the lower north western part of Ballut called Ghajn Tuffieha.

The company grew and expanded into new areas of the construction industry. A transportation arm was set up which was later incorporated into a new company with the children of another brother, Emmanuel. This company boasted the first trucks in Malta which were fitted with self-loading and unloading cranes to deliver construction materials directly to the building site.

Emmanuel Vella loading concrete blocks on a truck with a built in crane

The company also branched out into actual construction and development and also started tendering for construction projects. One of the very first projects that the company participated in was the new airport runway and its infrastructure. Other notable projects which Ballut participated soon after were the infrastructural works at the Marsa Dock and the Kordin Grain Terminal.

Working on the new airport runway

The demand for its products and the desire to produce new products led the company to move its base of operations from Ghajn Tuffieha to Wied Filep, limits of Naxxar.

Wied Filep was the site for quarries from the very beginning of the twentieth century (in fact the area provided the British Colonial government with construction materials) and the site was also known for the quality of its hardstone.

The new site allowed Ballut to manufacture new products such as ready mix concrete, prestressed concrete beams and precast roof panels. Ballut also invested in a new computerized and fully automated concrete block making machine that can produce 2000 concrete blocks per hour.

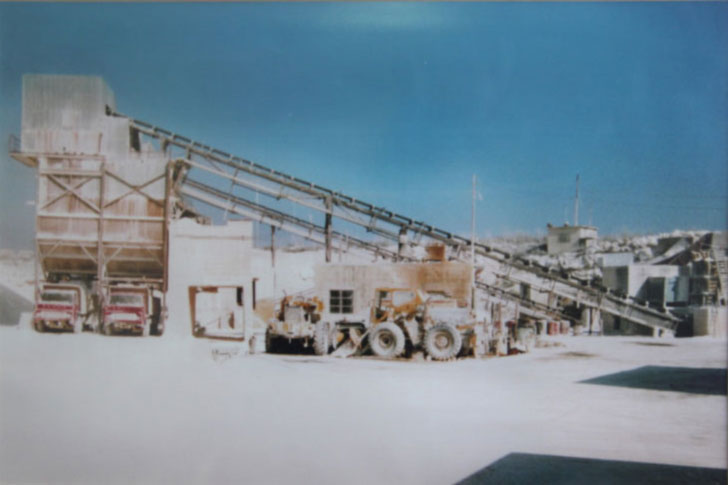

At the same time the company organized the whole process of rock cutting, stone delivery to the crusher and aggregate production in one contained area, therefore reducing the environmental impact. It also relocated the original quarry’s stone crushing plant from a public road side to a remote area. Plans are being made to restore the parts of the quarry that are no longer in use.

The original crushing plant at Wied Filep

To compliment this activity in 2004 Ballut acquired a precast plant, GPC, in Hal Far. The company was re-organized and new machinery added in order to produce a full line of precast solutions such as Hollow Core Panels, Precast Columns, Beams and Double Walls.

With the Delimara Power Station project, the company also started offering full construction piling services with a number of efficient piling machines. To this one must add that as the years went by the company also added a whole array of construction machines which gave it more flexibility and depth in the construction industry. These include bulldozers with earth excavating equipment, trenchers, steel bending machines, excavators and mechanical hammers.

The sum total of all this organization allowed the Ballut Group of Companies to tackle significant and diverse private, public and commercial projects on its own or as part of a consortium, such as the infrastructure for Midi Development in Tigne`, infrastructural work on the new Renzo Piano designed Valletta entrance, the new EneMalta Generating Plants, the first Smart City building and supply and installation of all the precast elements in the award winning Richard England’s “Dar il-Hanin Sammaritan” Conference Centre and Meditation Garden.

With more than a half century of experience and with the related incremental product and equipment solutions, the Ballut Blocks group is uniquely positioned to assist all the stakeholders in the construction industry.